Fireclay Sink Restoration

Large Fireclay Sink Restoration.

This was an interesting project we did for a customer in Palmers Green in London.

He had on old (and very large) sink made from fireclay in his kitchen. Usually these sink are recessed into a worktop and only the top and front of the sink are visible with the rest of the sink hidden.

However, the customer wanted his sink to be sitting on a support without any worktop around it and as a result the sides of the sink, as well as the front and top, would be on display.

Here is the bowl of the sink in question showing the wear typical of a sink of this type and age.

This picture shows one end of the sink and also what was unusual about this job.

When these sinks are made, one end never gets any porcelian glaze or enamel applied to it and also there are 4 circular holes just over an inch in diameter in this end of the sink, one on each corner. You can hopefully make out the two holes on the end of the sink closest to the camera.

The lack of glaze and the holes are part and parcel of the manufacturing process and generally it’s not a problem as this end of the sink is hidden from sight below the worktop.

However, it was a bit of an issue here with this sink what with it all being on display.

We filled and made good the holes on this end of the sink, as well as smoothed of the fireclay here as it was noticeably rougher than the rest of the sink which had been glazed.

Then we resurfaced the whole sink, including this end.

Here is the bowl of the sink. The bowl is now a uniform colour and the wear and staining has been dealt with.

Here is the bowl of the sink. The bowl is now a uniform colour and the wear and staining has been dealt with.

Repairing A Cracked Sink!

Edwardian Sink.

Cracked Sink Repair.

The cracked sink repair outlined below was done for an Edwardian Museum in Brighton. The Museum is actually a large house which was left to the local council by a prominent local family. The house shows what the homes of the rich were like over 100 years ago.

In one of the bathrooms there was an original sink what had a large, curved crack and a couple of hairline cracks around the waste. The sink itself had a fair bit of staining and wear which is not unusual for something this old.

This is the sink below. It has some nice features like graceful soap dishes and an unusual overflow.

The picture below shows the cracks around the waste clearer. If you look closely you will be able to make out 2 hairline cracks coming up from the waste to the left hand side of the main crack.

There was also a lot of discolouration and crazing in the area.

The brief for this job was to repair the cracks but to retain as much of the staining and discoloration as possible as this was, after-all, a museum and if the sink was made to look too pristine and perfect, it would no longer look like a genuine antique.

The first step was to open up all the cracks as much as needed to allow us to inject a two part glue into the area. This makes the area rigid and prevent the cracks from continuing to grow which is what tends to happen with things made from porcelian, such as this sink. Then the cracks were made good with fillers.

Finally a colour was made up. On a sink like this it can be tricky as the staining and wear mean that the surface is actually a hodgepodge of different shades of white. We had to choose an area of the sink to match the colour we made to. A colour was made up which matched the colour of the sink 2-3 inches above the cracks.

The made up colour was applied, covering the cracks. You can see the result below:

The cracks have gone. Unfortunately this meant we lost the strong discolouration that was just above the waste. But the colour we made up blends well so this look very natural. Also, the colour application was kept as local as possible which meant a lot of the other marks and dis-colouration around the waste were retained.

The final picture shows most of the sink and the repair:

George Jennings Brought Back From The Dead

[pe_estro_slider id=”5″]

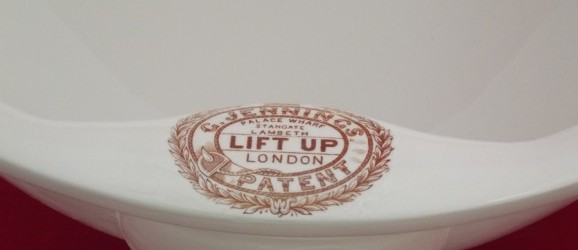

This is a rare tilting sink by George Jennings. We do not have an exact date but these sinks were quite early (circa 1860) and were one of the designs one comes across before the waste and overflow became pretty much the norm for basin design.

Here is the basin in situ prior to restoration work.

George Jennings himself was one of the giants of Victorian Sanitation. It was his toilets which were introduced at the Great Exhibition of 1851 in the Crystal Palace in London. This was the first time many people had the chance to use a flushing toilet and many, many people went ahead and did so. Over 800,000 people paid over a penny each to gain access to this new and exciting experience. It seems strange to us now but the impact the toilets at this exhibition made was massive. The phrase “to spend a penny” meaning “to use the loo” stems from George Jenning’s toilets. And within 4 years of the exhibition there were over 200,000 flushing toilets in London alone. Now the very idea of not having a flushing toilet in your home is completely foreign and unacceptable.

The tilting sink was a design the allowed the sink to swivel round on two pivots to be emptied. There was no plug hole.

It looks like the tilting sink was introduced after 1851 but before the turn of the century, as it seems to appear after the Great Exhibition of 1851 but was still referred to as “Jennings’ patent tilt-up and lipped lavatory”. What we now call the “wash basin” was called the “lavatory” until the turn of the century! A bit confusing sometimes. When discussing antiques we do sometimes forget and call the item a lavatory instead of a sink.

The basin itself was in a pretty sorry state and had many cracks and repairs on it. It appears as though the basin had had different repairs done to it on at least 3 separate occasions. Some of the repairs were held together with glue, some with a white hard paste and one particular area with staples. Staples or riveting was a common way to repair ceramics from the 18 century up until approx. 1910. We think this basin may first have been repaired circa 1885.

Here are some pictures showing the basin prior to restoration and with the poor repairs.

Some of the repaired pieces of porcelain were sitting proud of the rest of the sink, especially around the edge.

The first thing that was done was to break the bowl back down into its pieces and clean off the glue, etc that had been used in the previous repairs.

Then the bowl put back together with the parts fitting as tightly together as we could get. Sometimes this required grinding small areas away to allow the pieces to slip together. Once the basin was all back together there were still some areas sitting a little high.

To handle the high areas the basin was treated with high build primers and fillers to smooth out these areas.

Then the basin colour was matched and the basin sprayed.

The brass pivots need to be re-attached, but this is going to be left until the basin gets back to its home and the positioning of the pivots can be checked to ensure they are fixed in exactly the right place.

Then the pivots will be fitted in place using a putty mixture which is what was used originally for this type of work.

Here are some pictures of the basin after restoration. Hopefully we will get some pictures from the client with the basin in situ again and ready to be used again for another hundred or so years!

REPAIRING A SMASHED WASH HAND BASIN

We often get calls from clients asking us if it is possible to repair cracked sinks or even broken sinks. Until recently basins with extensive damage could not be repaired. However we at The Bath Business are continualy trying and testing new procedures for all our bath re enamelling work. We can fix all of these problems with a sink or wash-hand basin due to our innovative research and work. Our technicians are highly skilled and the best in the repair & re enamelling business as far as we are concerned. Despite our confidence in our ability to do a good job for our clients we had never had a basin that had been completely smashed. So a smashed wash hand basin was new for us.

I got a call in the office from a chap called Colin Slater. He had bought a beautiful basin and was very excited about getting it home. He was busy renovating his property with his partner (an architect called Singa Govedi) and this wash-hand basin was part of their renovations. They had searched for the perfect basin for their bathroom. Colin worked long hours as a Deputy Head Teacher in a London school. As you might imagine it was hard enough to fit everything in with work and also work on the property at the same time.

The Clayton Sink was perfect for their project and completely in keeping with the style of bathroom they wanted. As well as being a lovely sink it also had a gorgeous cast iron wall mounted frame that it sat in. It was a lovely antique basin. It was being delivered from Yorkshire. Colin was so excited about the basin arriving he was looking out of his window as the van pulled up. To Colin’s horror he watched in slow motion as the package was DROPPED out of the back of the van. The results were not surprisingly devastating. The basin was completely smashed to pieces. Colin was very upset as this was an important part of their restoration work.

By the time Colin had called us he had already spent around 60 man hours putting the wash-hand basin back together. His partner had then spent around about 240 man hours filling and sanding the basin. It was a very labour intensive undertaking but they loved the sink so they wanted to have it saved from the rubbish dump. After all it was an antique and had survived so far.

Colin and his partner had done a great job thus far but they now needed to have the basin re enamelled professionally by a reputable expert restoration company. They wanted to keep the logo. Also they wanted the original colour to be maintained. This meant we would need to do some special restoration work to retain the logo and make the colour of the basin to get a perfect match.

They were delighted with the result on the sink and the fact we’d retained the logo whilst resurfacing the rest of the sink. What do you think?

As you can see in the above photo the basin is fully restored and has the logo retained. Apparently the basin causes gasps of amazement from Colin & Singa’s guests.

This wash basin is a good example of a Victorian basin with cast iron frame. If you would like to purchase an antique basin such as this or any other traditional design contact us at The Bath Business. We can source original antique basin supply quality reproductions, or, if you are looking for something particularly special let us know and we will source this for you.

For more information on our re enamelling and restoration works please contact us on 07967333030.

If you like this BLOG post please subscribe so you can be updated when we’ve posted others.

VIVE LA DIFFERENCE!

We got a call quite a few weeks ago from a lady in Woking whom our services had been recommended to.

She had just moved into a fantastic new home and inherited some amazing Antique roll top baths and French basins. She had some lovely antique French wash-hand basins which required full restoration work. One had a large crack, the taps needed reconditioning and nickel plating etc. Have a look. You’ll see they are quite special basins but definitely in need of some TLC.

It took around about 12 days to do all the work required on the basins. We had to re-condition the taps and silver nickel plate them, replace a set of taps withoriginal antique French lever taps, silver nickel plate the wastes, covers etc and we also had to rectify the cracked sink after which point we could then re enamel both wash-hand basins whilst retaining the logo in one of the basins. It was quite a lot of work but we were quite pleased with the end result as was the owner.

Above is the basin with the crack rectified, new taps, new old style plug and chain and re plated waste. It’s a very unusual French basin. Finding the taps was a minor miracle. We think this particular set of taps are actually the original taps that the basin had on it when it was made. There is a special fitting for the tap that would have been made specifically for the basin they were being attached to and this particular set of taps fitted perfectly! So somehow we brought them back together again after many years apart.

Here is the basin with the logo “SUPERBUS Patent” retained after the re enamelling work. The basin also has the waste replaced & the cover, plug and chain stay nickel plated as well as the taps reconditioned and then also plated. Quite lovely.

If you have any antique sinks with cracks or taps needing restored please contact us. If we can’t do the work in situ we will more than likely be able to do the restoration work at our workshop.

Do let us know what you think of these little beauties. If you would like updated on any of our special offers or new items for sale please follow us on Facebook.

JOHN BOLDING ANTIQUE BASINS RESTORED

We were asked to restore some old antique sinks in an old property. When we arrived we found a lovely old property having its original features, fixtures and fittings restored and renewed. As there were over a dozen bedrooms it was a relatively big undertaking.

The basins were part of the restoration work so we were called in as the restoration experts to restore them. We had to repair some cracked sinks. We did also restore some fantastic antique baths in this property.

The basins we were asked to restore were in the bedrooms. As an aside the bedroom vintage wallpaper looks fantastic! There were quite a few sinks that were cracked or completely broken. Repairing cracked sinks is a specialist job.

The fact that the basins had lasted so long was amazing. They were original John Bolding Basins from the first Bolding works. This dates the basins circa 1880-1890.

John Bolding and Sons Ltd were great rivals of Thomas Crapper & Co ltd and in 1963 John Bolding and Sons ltd became the owners of Thomas Crapper and Co ltd. The basins by Bolding are quite distinctive and very aesthetic.

John Bolding and Sons Ltd were great rivals of Thomas Crapper & Co ltd and in 1963 John Bolding and Sons ltd became the owners of Thomas Crapper and Co ltd. The basins by Bolding are quite distinctive and very aesthetic.

Normally these particlar sinks would be beyond repair. However we have developed an innovative restoration process which we have been using for the last 18 months with great success. So now whereas architectural salvage company’s or private individuals were having to dispose of beautiful antique basins we can restore them. We think we are the only bath and sink restoration company that can fix sinks with cracks or damage such as this.

Once repaired we would normally resurface the sinks completely. They would look fantastic, feel fantastic and look virtually new. However the John Bolding Emblem/Logo would be lost. That was not an option in this situation. So we had to very carefully colour match and blend in our restoration work so that the sinks were renewed but the repairs were virtually invisible and the logo stayed intact. Thus preserving the heritage and integrity of the sinks. As you can see the results are fantastic. Restoration work like this is priceless. These basins could have ended up being thrown out with all the history and heritage lost with them. Now they can be admired and used for the next 100 years.

If you have some historic or antique basins, baths, bidet or toilets you would like to salvage and bring back to life contact: The Bath Business, The Bath and Basin restoration specialist. They can help you.

Add us to your circle

Add us to your circle